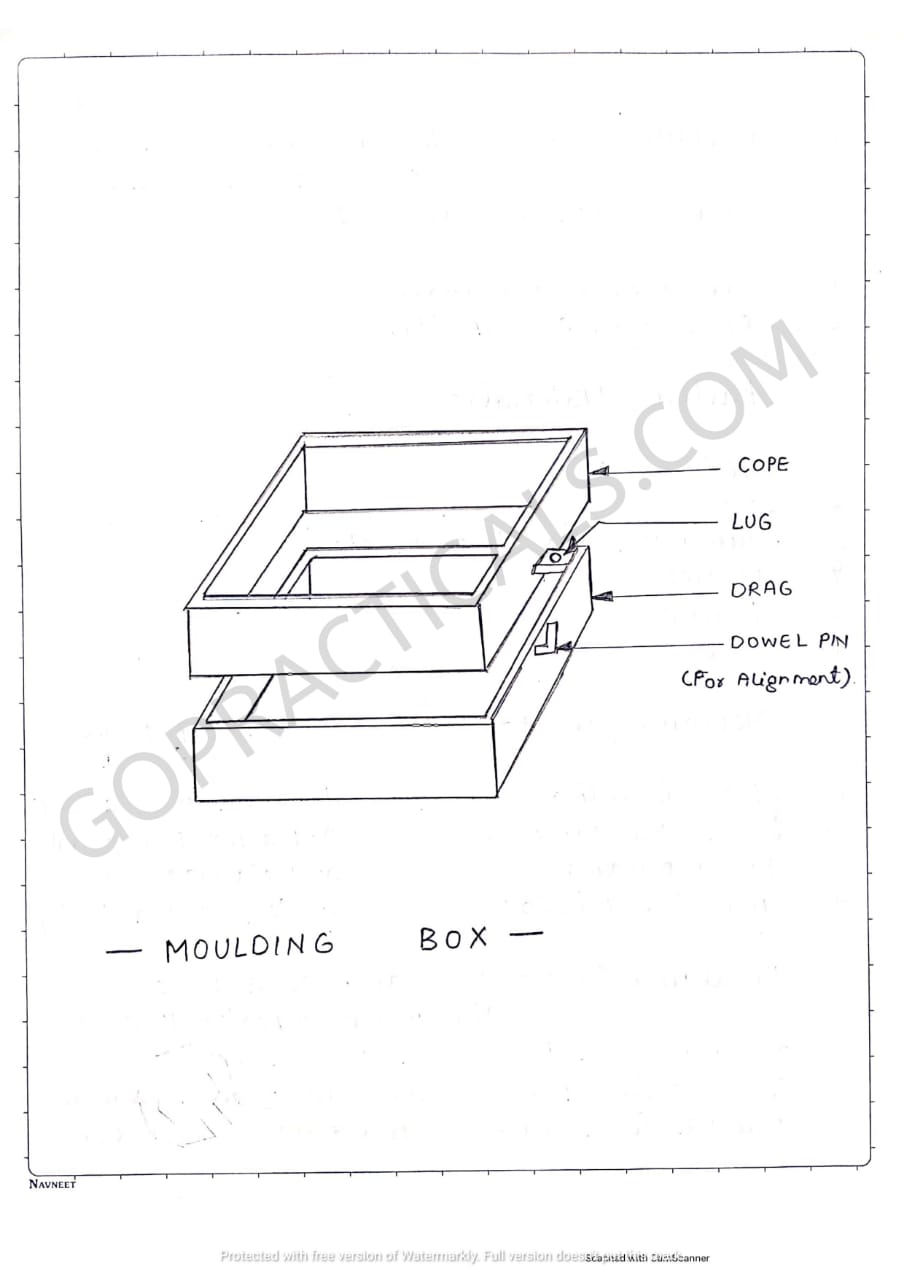

Foundry technology involves molding, melting, and casting of parts; that is, producing castings by filling the prepared molds with molten metal alloys (mostly aluminum). This is a unique primary metal processing method which must be imparted to most engineering students. The practical work enables the students to gain expertise and confidence in foundry activities.

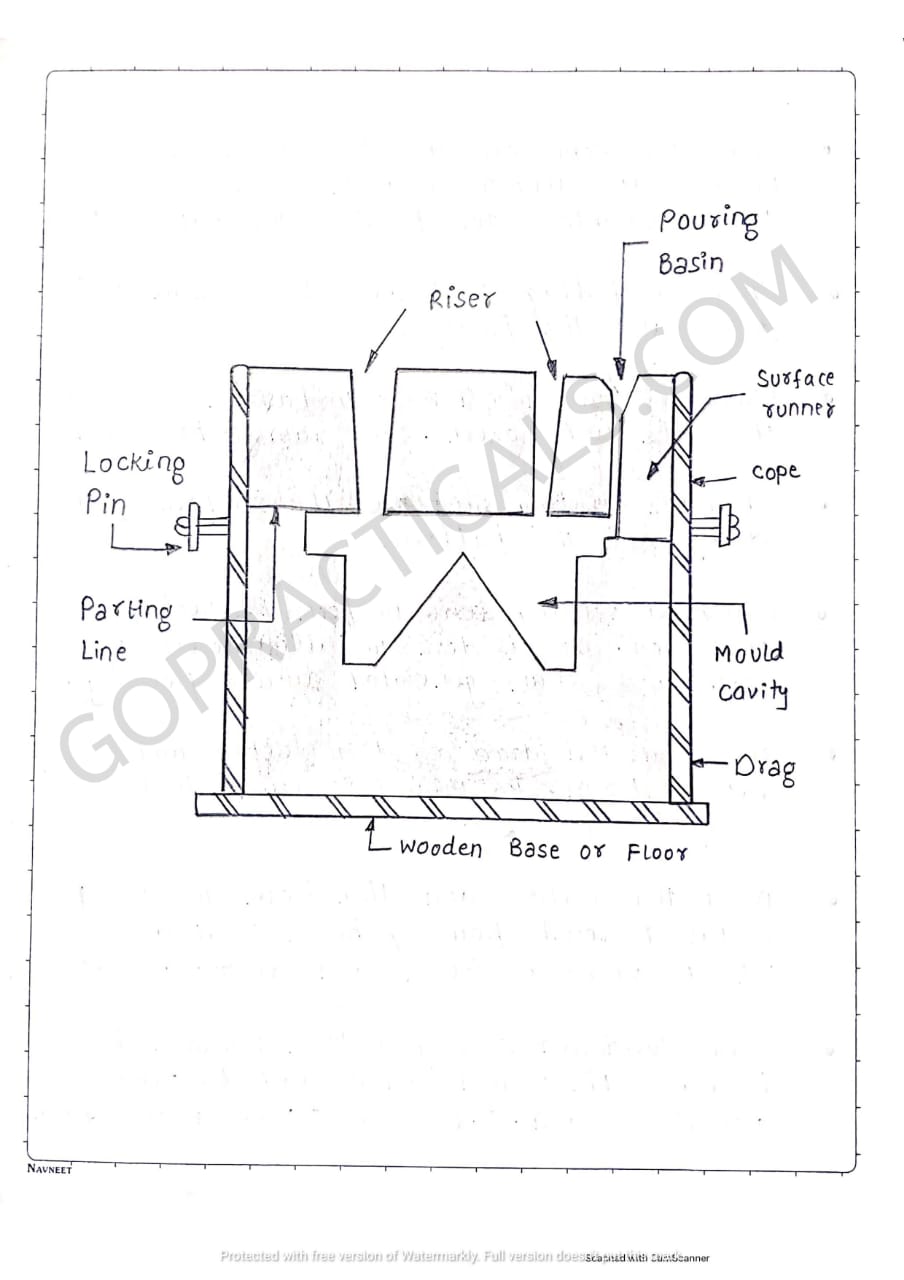

In metalworking, casting involves pouring liquid metal into a mold, which contains a hollow cavity of the desired shape and then allowing it to cool and solidify. The solidified part is also known as a casting, which is ejected or broken out of the mold to complete the process.

Video on Casting Aluminum Process Using Sand Mold

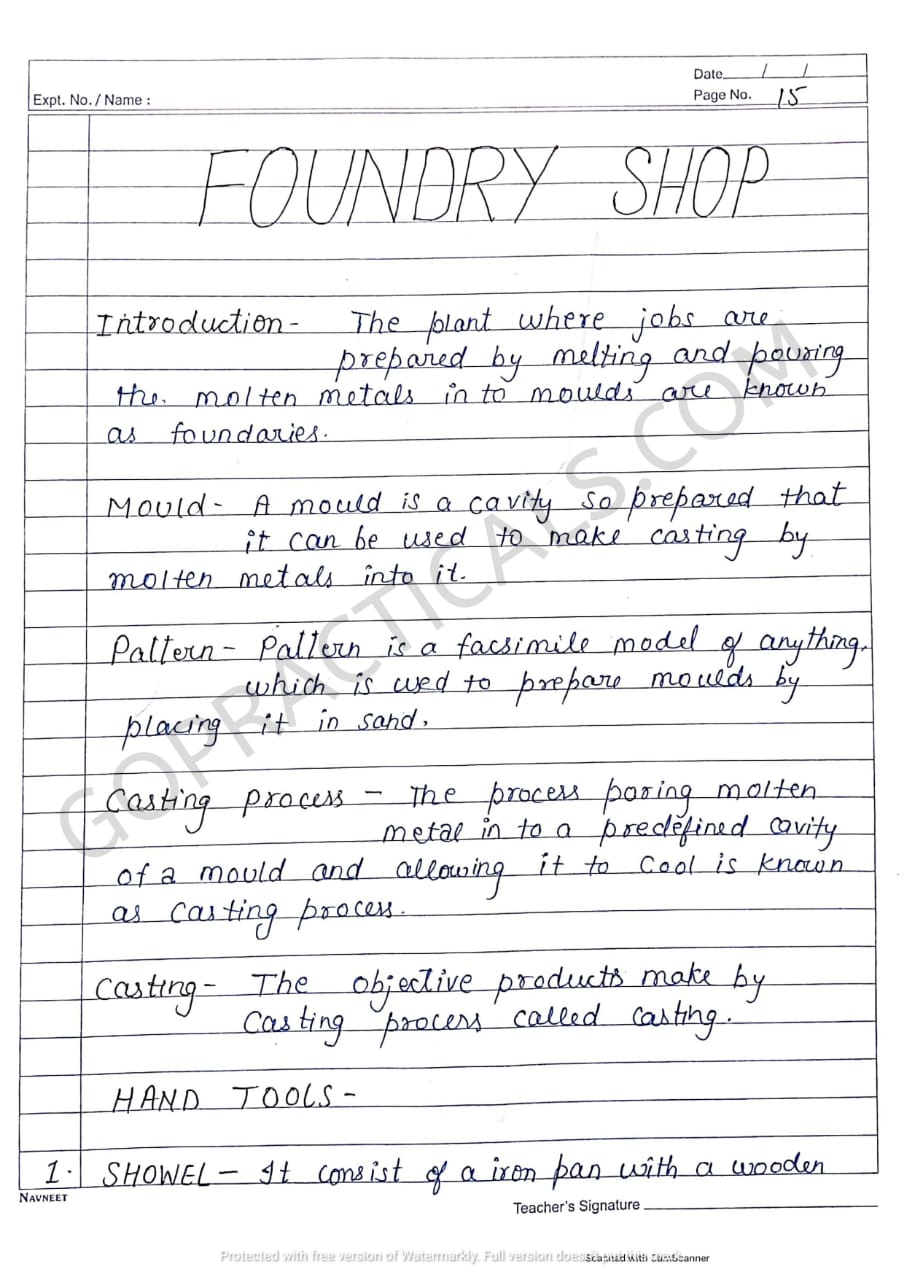

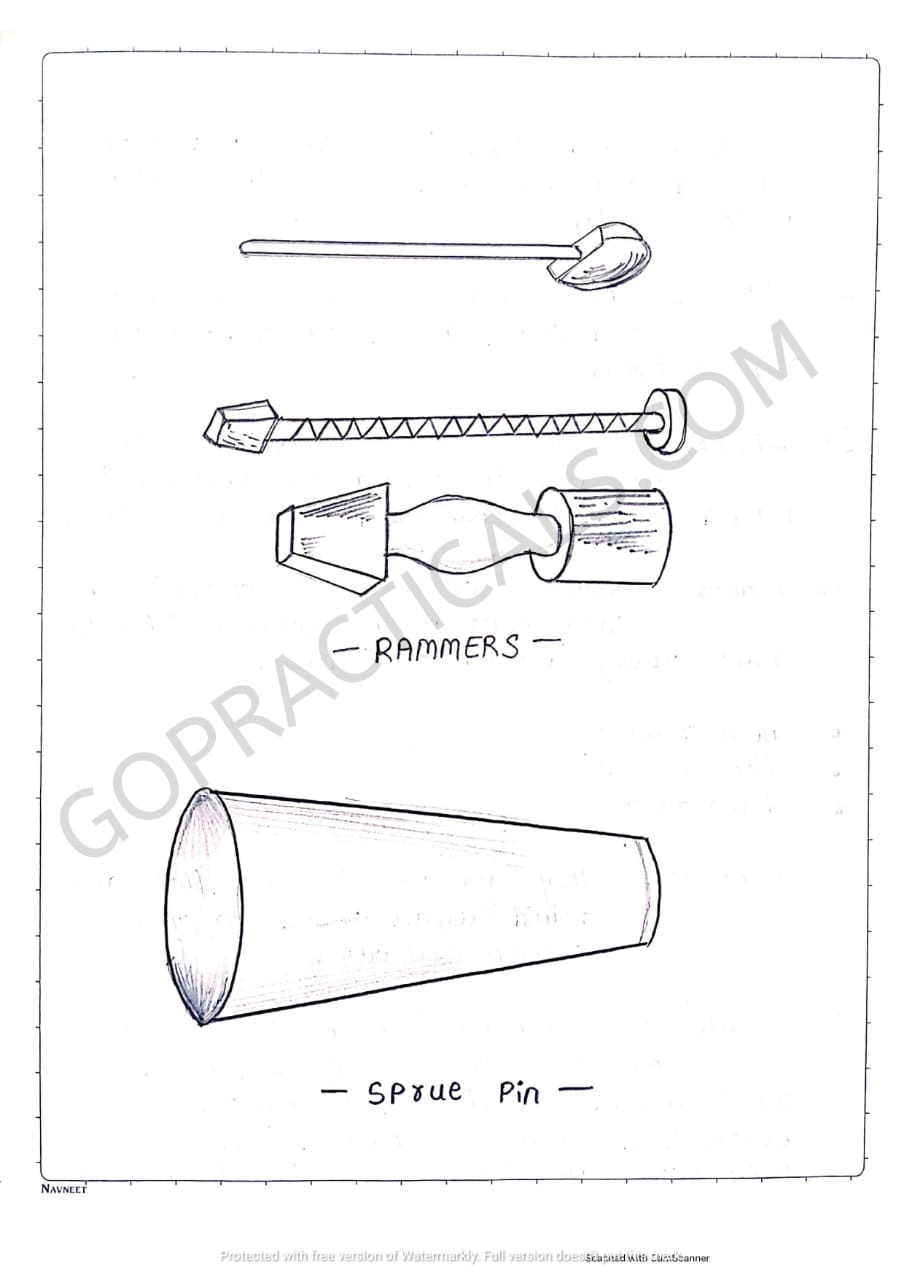

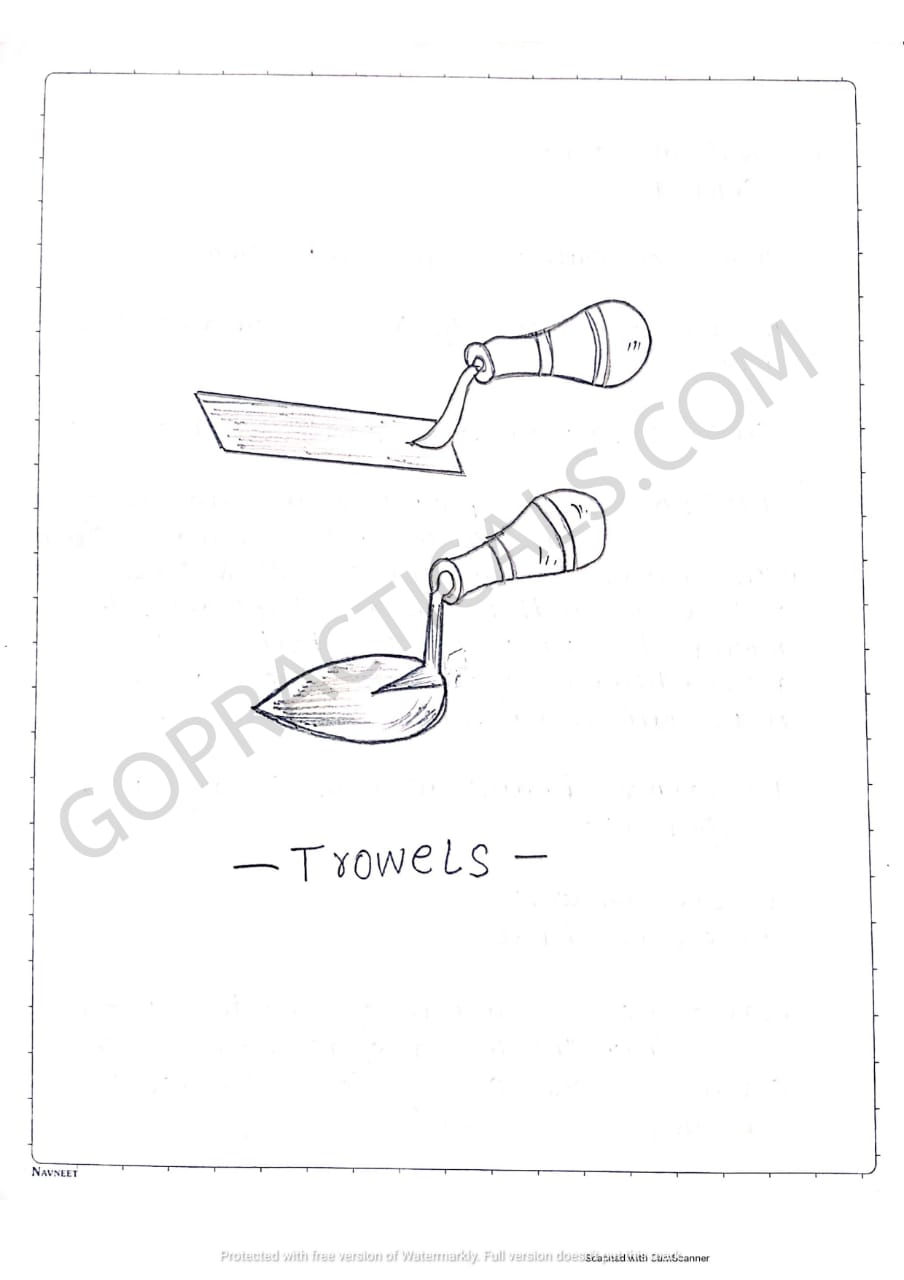

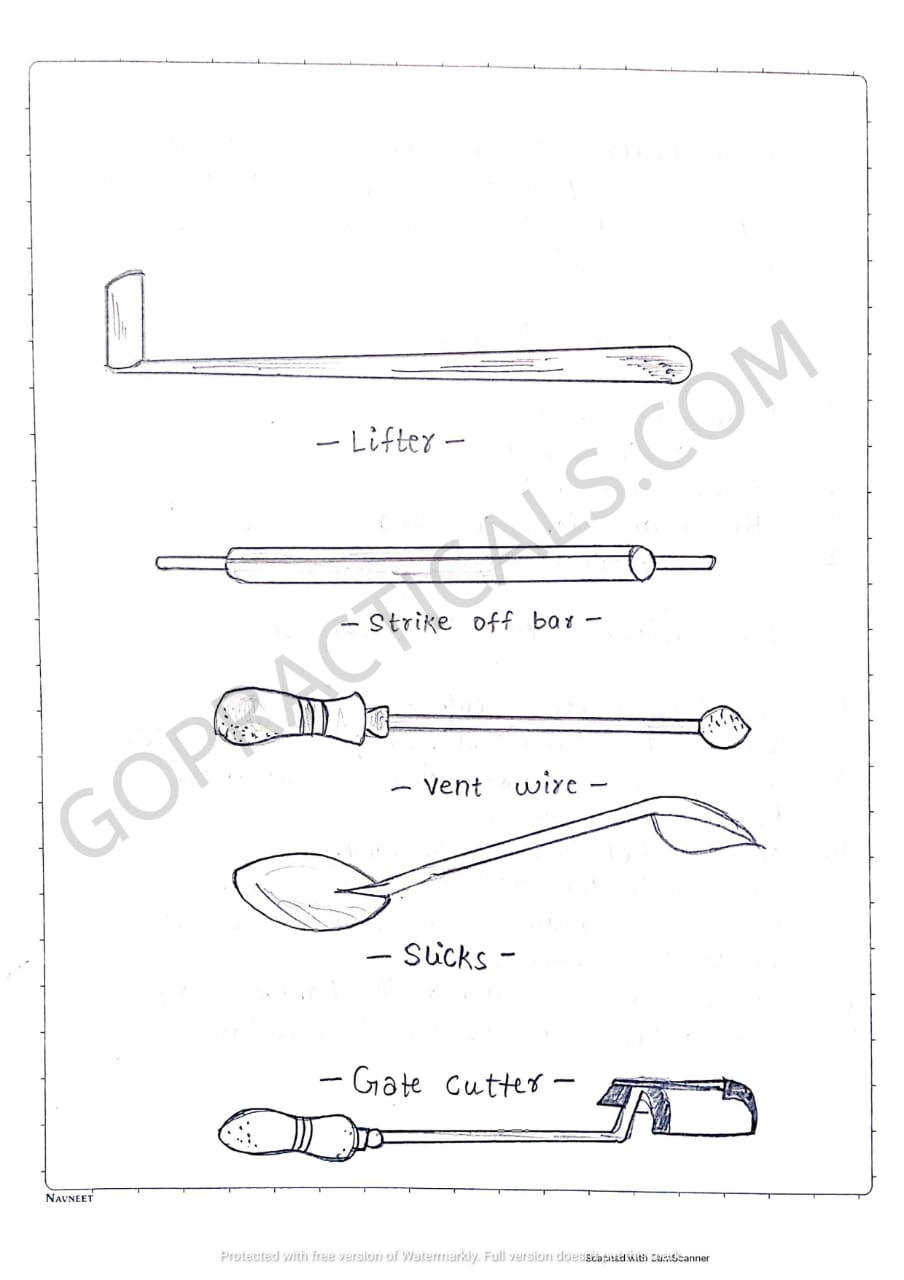

FOUNDRY SHOP : Introduction, Tools and Precautions – Workshop Practical

Really amazing information keep it up